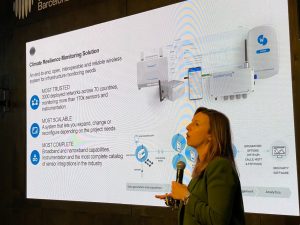

At MWC2026, Izabela Zrazińska from Worldsensing presented DINAMINE, highlighting the project’s mission, expertise, and its contribution to European innovation initiatives.

During a session aligned with the EU Strategic Agenda 2024–2029, she showcased DINAMINE alongside other EU-funded projects in which Worldsensing is involved.

Strong European collaboration fuels greater innovation, and DINAMINE is proud to be an active contributor to this shared progress.